Plastics Industry

Precise, Energy-efficient and Smart – Our Automation Solutions

Today’s rapidly changing market requirements is a never-ending source of new challenges – in particular in the plastics industry.

Among these is the massive cost pressure, which is further impacted by more and more quality and safety regulations in production. Constant changes, increasingly complex products, shorter product life cycles and faster production processes are leading to a greater need for expertise and skilled labour.

Why we offer the perfect automation solution

We support you every step of the way

-

Many years of experience in the automation of plastic and hybrid parts

-

Machines are readily available thanks to standardised modules

-

The robust design ensures a long service life for your systems

-

We offer you everything from a single source – from design to commissioning

-

Short delivery time

-

Smart robotics through nexofox

» No need to acquire additional IIoT expertise

» Malfunctions and alarms can be viewed from a remote location

» Entry into the IIoT world

Process steps of injection moulding automation

-

Insert preparationThe preparation of inserts for overmoulding in plastic injection moulding machines comprises various processes. The correct positioning of the parts in the cavity distance of the injection moulding tool is described backwards from the insertion. The inserts may have to be heated up beforehand to prevent the temperature from dropping during the overmoulding process with the hot plastic. Preparation of the inserts also includes pre-cleaning, such cleaning of punching flakes with ionised air for contacts that are punched out of the coil. However, inserts must first be positioned in a way suitable for automation. This can be done through automated removal from palletised trays, as well as via a bulk material feed using a feeder or vibrating spiral conveyor, or even from a punching and bending device directly from the coil of a punching machine. Automatic tests often have to be carried out between the individual steps in order to verify the condition of the inserts with regard to process ability.

-

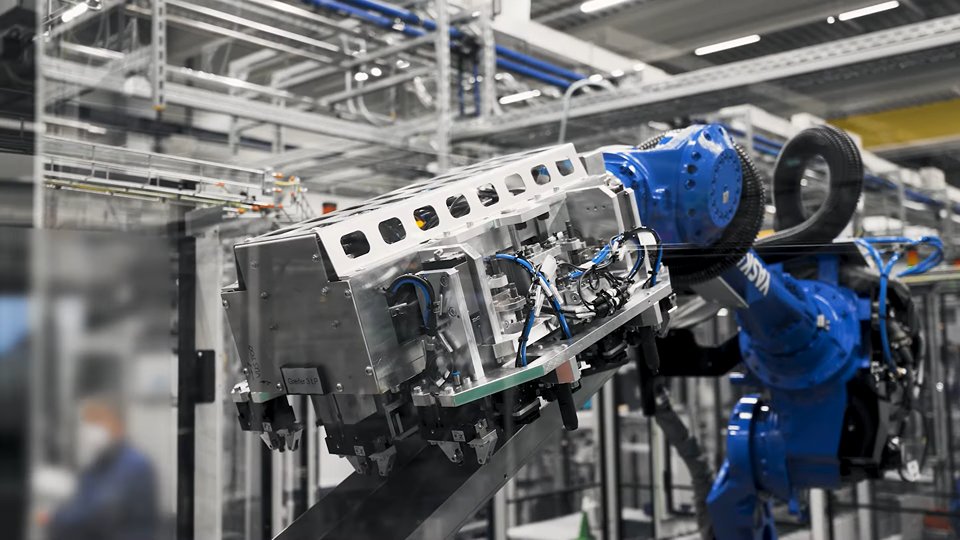

Insertion and RemovalMinimising the mould open time during insertion of the inserts and removal of the finished parts is essential for the maximum output of a system. Absolute precision is also required when transferring the inserts to the injection mould and when removing the finished parts and sprue accurately and completely. To this end, special docking devices which actively position the gripper on the injection mould are attached to the multi-gripper tool. The inserts are usually inserted and transferred into the mould cavities via active, individual feed movements. The corresponding safety signals from the Euromap interface of the machine are used for safe insertion and removal and synchronised with the correspondingly defined safety areas in the robot controller. If no hot runner mould is used, the sprue is safely removed and disposed of.

-

Post-processing of finished parts, testing and markingAfter the injection moulding process, workpieces often have to cool down before further testing and processing. We effect this either by means of active cooling or a corresponding cooling section. Afterwards, a shot – which usually consists of several parts – is then separated into individual parts. The various post-processing and testing steps then follow individually, usually on a rotary indexing table with several stations. These can be: visual and electrical checking of connectors and contacts (swash circumference test, gauge pin test, isolation test), assembly processes such as mounting brackets, ultrasonic welding or hot caulking of add-on parts. This is usually followed by a labelling or marking process. This can be a simple dot that is applied to parts that have already been tested using a hot tip, adhesive labels with part information, or inkjet or laser labelling in plain text or as a data matrix code.

-

Packaging and PalletisingThe finished parts finally undergo automated packaging for further processing in line with automation requirements or for careful and safe onward transport. A wide variety of forms of packaging and packaging equipment are used for this. These can be transport packaging specified by the customer or trays or workpiece carriers for in-house transport for automated subsequent processing. We use both our standardised SUMO palletising system and EGS special palletising solutions. We can offer comprehensive solutions right through to palletising on Euro pallets ready for dispatch, including shipping labels and film.

Process chain

Downloads

Popular application reports

Do you have any questions on this product? Would you like individual advice, or to request a non-binding offer?