IIoT solutions from nexofox for automation systems from EGS Automation

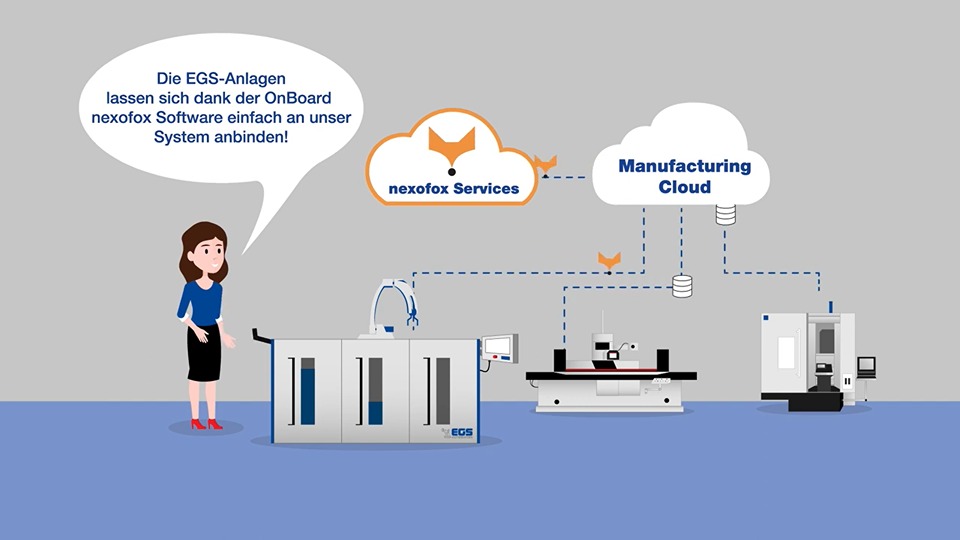

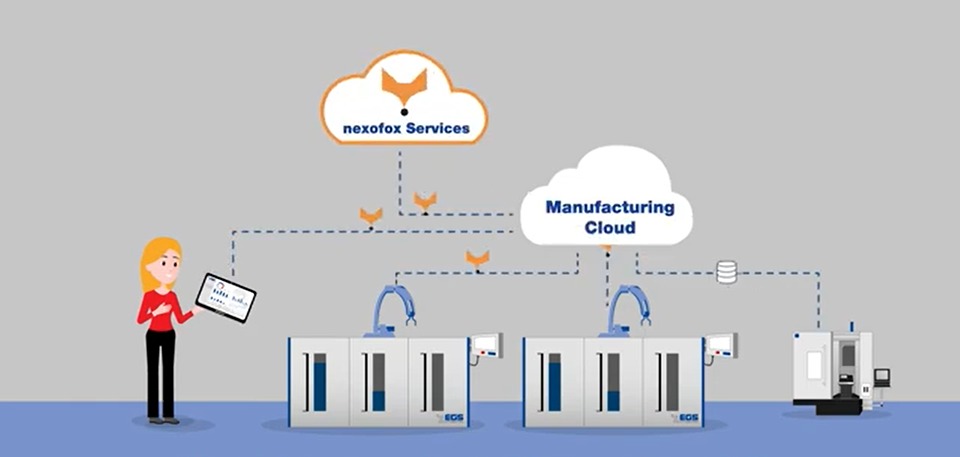

Nexofox offers its smart services and IIoT solutions not only for Dunkermotoren motors, but also for our robot and automation systems. Permanent condition monitoring of automation systems or individual units and components of a system as well as preventive maintenance are essential building blocks for maximising productivity. It helps prevent downtime and breakdowns, which in turn helps to avoid supply bottlenecks.

From the field to the cloud, nexofox facilitates simple integration into existing systems. Our nexofox team supports you along every step of the way, from your initial consultation and joint concept development through to partnering with you to realise your project.

Videos

3 reasons for choosing Smart Robotics with EGS Automation

Our nexofox services for your automation system

-

Condition MonitoringCondition monitoring refers to the permanent monitoring of the status of process parameters of a system or system components. This makes it possible to monitor systems from a remote location, from anywhere in the world, from your desk or smartphone. In addition to obtaining pure operating data such as piece counters, system statuses and error messages, collecting data and recognizing dependencies means that several parameters can be used to draw conclusions about fault conditions in order to prevent faults and thus avoid downtimes. Measures for repairs and maintenance can thus be planned in advance, which results in cost reductions.

-

Predictive MaintenancePredictive maintenance is a preventive maintenance process that does not take place at a fixed time interval in the way maintenance used to be performed, but is triggered by process and machine parameters that are permanently monitored. With the help of predictive maintenance, projections can thus be made for maintenance work. Faults or wear on machines are recognized at an early stage. If, for example, the torque curve of a robot axis changes gradually over a certain period of time, it can be deduced that the gearbox will soon need to be changed and this can then be done during a planned shutdown. For example, by recording the alternating cycles of an axis, loads on cable assemblies that are moved as a result can be determined and a preventive inspection or replacement can be initiated.

Preventive maintenance vs. predictive maintenance:

preventive maintenance is more like an annual health check, where maintenance is carried out regularly to prevent breakdowns. Predictive maintenance is based on real-time machine data that uses sensors to record measured values such as temperature, vibrations and pressure.

-

Remote MonitoringRemote troubleshooting and rectification can be offered via remote maintenance access, as can function or sequence programme enhancements for the robots and motors of a system or machine. Faults and malfunctions in a robot system can be analysed and rectified to a very large extent via remote maintenance access. This saves travelling costs and reduces downtimes.

An industrial robot offers great flexibility in terms of movement and program sequences. If additional functions and processes need to be integrated at a later date, this can also be done with remote access.

-

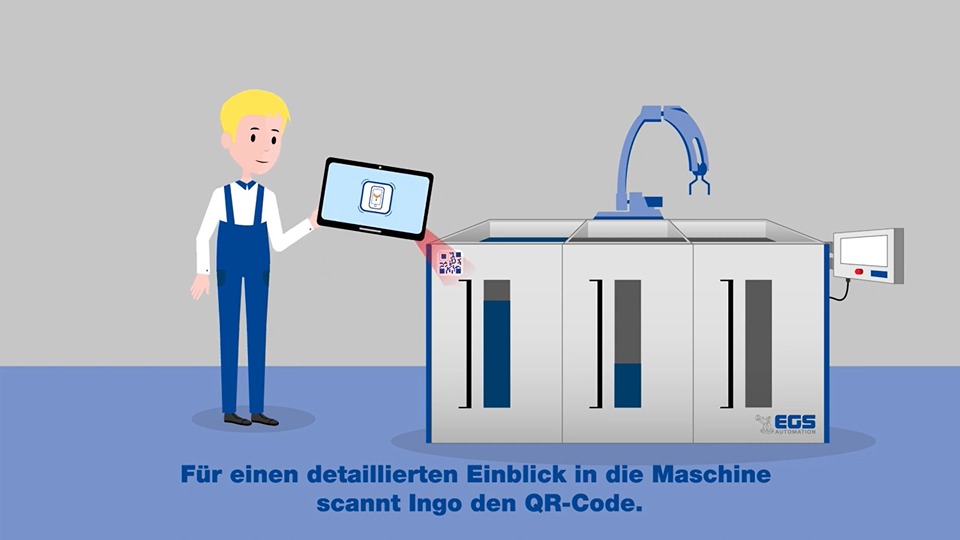

Smartphone apps[The nexofox team not only supports you with programming and configuration of software solutions at IIoT field or cloud level, but has also developed their own app especially for service technicians. This app that was developed in-house supports the service technician with all the necessary data when working on site.

-

Open standards - Integration into ecosystemsThe individual modules and components can be integrated through all common interfaces. With OPC UA, we offer the most important market standard that has become established for platform-independent data exchange. Wit regard to integration, we use open standards which are easily incorporated into various ecosystems.

-

IT SecurityIt goes without saying that we handle your data with great responsibility. We comply with the highest security standards right from the design stage. Our interface between the EDGE and our cloud is already IOS 27001 certified. Our objective is holistic certification, from the level of the field to that of the cloud, and this is already being planned. With the progressive increase in certification, IT security is becoming more and more interwoven into our development processes, making it an even more important part of our DNA.

Contacts

Service und Support

For further information or to discuss your project idea, please contact us directly via our contact form or the following email address:

support.nexofox@ametek.com

support.nexofox@ametek.com