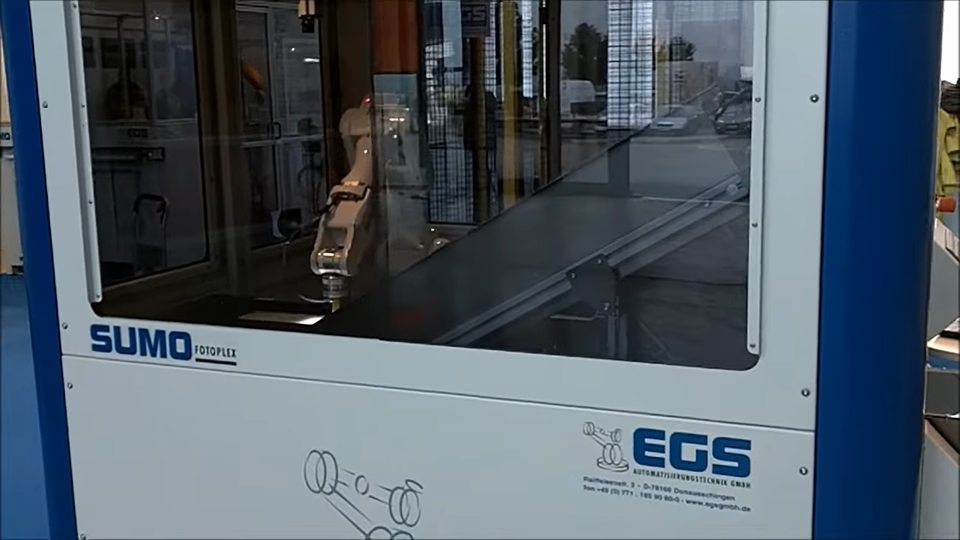

SUMO FOTOPLEX

FLEXIBLE, VERSATILE, PROFITABLE

A flexible universal feeding system for randomly arranged workpieces

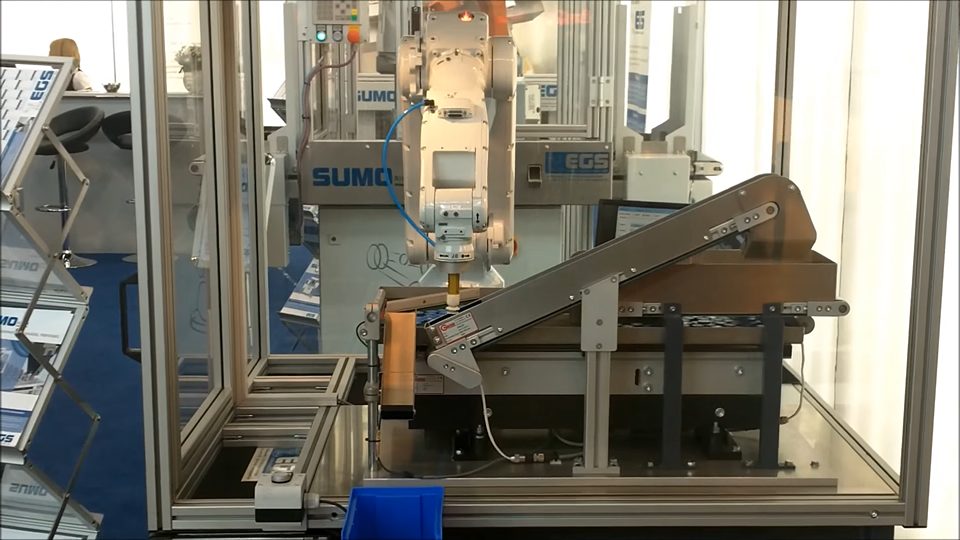

The SUMO Fotoplex is a clever feeding solution for automating your handling and production process with randomly arranged workpieces.

Workpiece handling is done with precision and reliability by an industrial robot with a built-in image processing system that offers the necessary flexibility for workpieces of different sizes and geometries. Workpiece-specific gripper tools ensure precision pick-up, transfer and placement of parts. Workpiece storage and feed is done from bulk materials. In this way, randomly arranged workpieces can be positioned for further processing.

The SUMO Fotoplex is ideal for all types of microparts and small parts. SCARA and 6-axis robots of different sizes can be used depending on the required cycle time, workpiece weight and size, as well as the required workpiece orientation. In conjunction with another SUMO palletising system, randomly arranged components can be positioned and inserted into workpiece carriers.

Specifications

-

Technical Data

Robot load capacity upto 10 kg Robot reach upto1.101 mm Robot motion systems Scara (4 axes)

Articulated arm (6 axes)Tool places 3 Camera system 2D/ 3D position detection incl. orientation Lighting Transmitted or incident light Feeding system Recirculating conveyor or feeder Special version 2 or 3 robots Space requirement Area approx. 2.16 m x 1.24 m, height 2.00 m Weight approx. 800 kg

Any questions on this product? Please feel free to contact us!

CONTACT US