SUMO OPTIPLEX

ADJUSTABLE, RELIABLE, COMPACT

The economical, flexible automation system for your deburring process

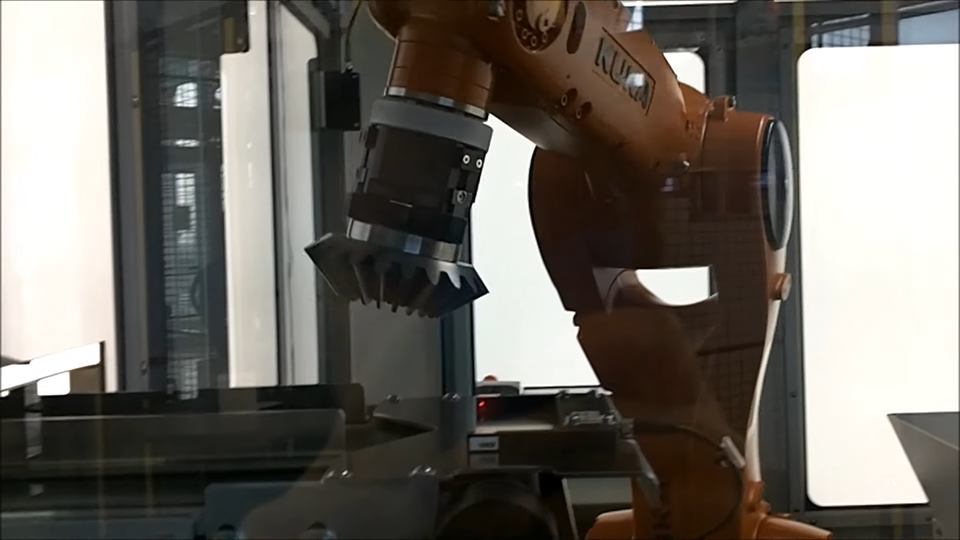

The SUMO Optiplex is an adjustable and reliable solution for automatic deburring of different workpieces.

Workpiece handling is done with precision and reliability by an industrial robot that offers the necessary flexibility for workpieces of different sizes and geometries. Workpiece-specific gripper tools ensure precision parts pick-up. Specialised deburring tools for various deburring methods enable consistently high quality. After pick-up and alignment of the components, the robot performs the various processing operations automatically and with precision. The deburring contours are precisely aligned within the cell using appropriate sensors. The component can be reoriented using an optional turning station.

Specifications

-

Technical Data

Robot load capacity upto 12 kg Robot reach upto 1.440 mm Max. part weight 7 kg Tool places 3 Deburring processes Milling, countersinking, drilling, brushing, grinding, cutting

Workpiece alignment Camera, sensor or device Space requirement Area approx. 2.16 m x 1.24 m, height 2.00 m Weight approx. 80 kg

Any questions on this product? Please feel free to contact us!

CONTACT US